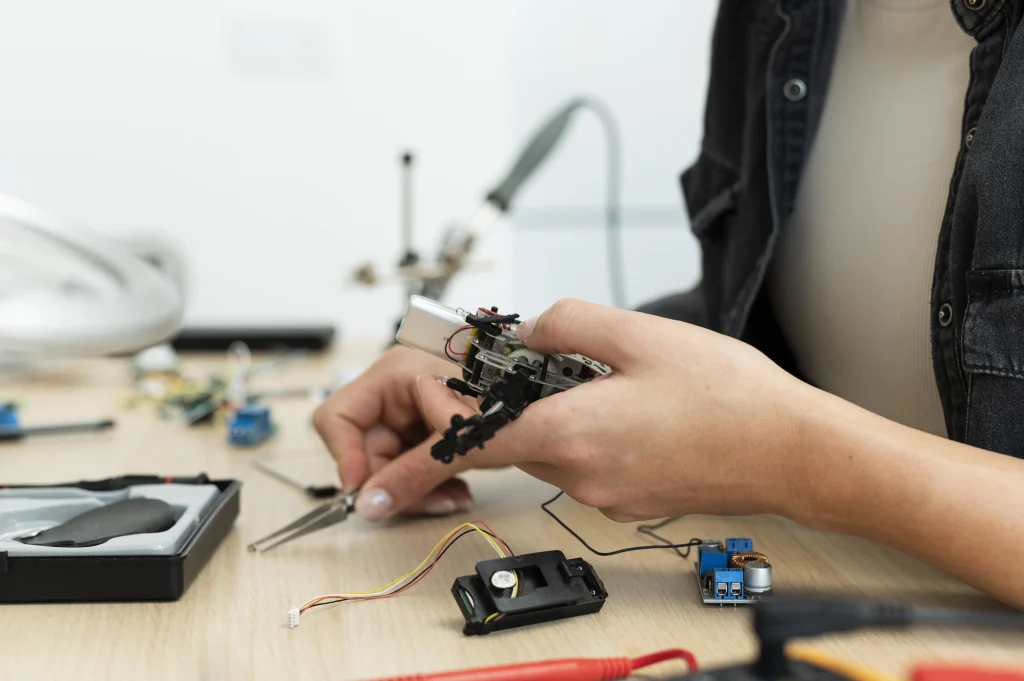

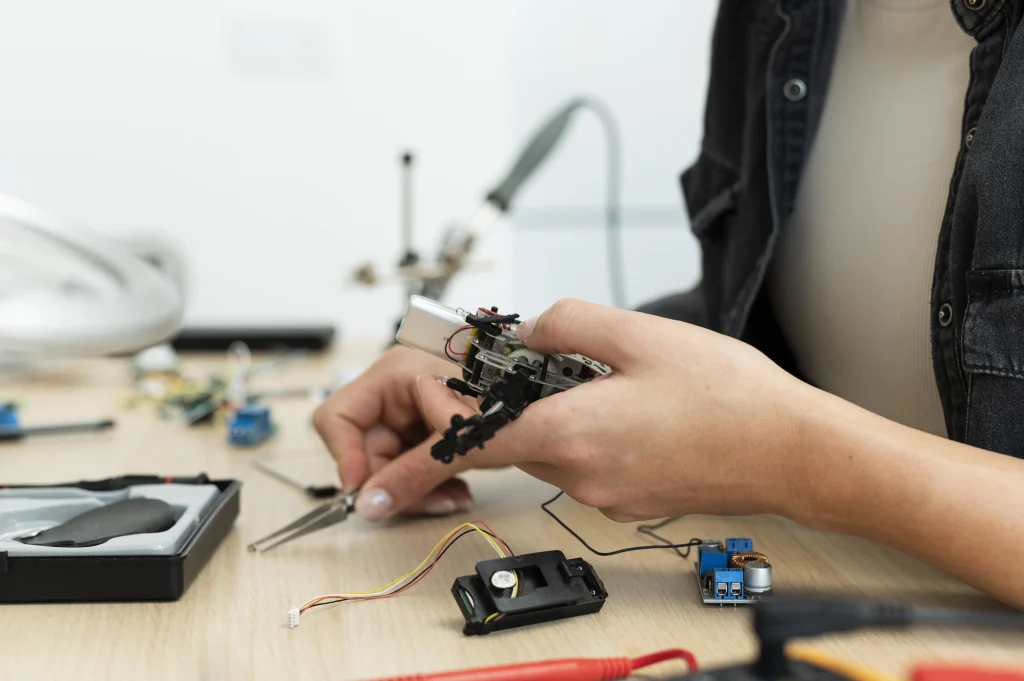

Precision Module Assembly Services in Malaysia

Smartlink Engineering delivers high-quality module assembly services tailored to the demands of global manufacturers. Based in Malaysia, we specialize in integrating complex electromechanical components—including PCBs, cable harnesses, connectors, housings, and control units—into ready-to-install modules. Our clients in the automotive, electronics, industrial, aerospace, medical, and energy sectors trust us for flexible production capabilities, stringent quality control, and seamless global delivery.

Why Choose Smartlink for Module Assembly?

Trusted by global manufacturers, Smartlink Engineering is a preferred partner for precision module assembly in Malaysia. Here’s why companies around the world choose us:

- ISO-Certified Quality Assurance

- Industry-Specific Expertise

- Flexible Production & Fast Turnarounds

- End-to-End Service Capabilities

- Cost-Efficient Malaysian Manufacturing

- Global Export Experience

Our Capabilities: Precision Module

Assembly You Can Trust

At Smartlink Engineering, we provide comprehensive module assembly services tailored to meet your product and production goals. From initial subcomponent integration to final functional testing, our capabilities are designed to ensure efficiency, reliability, and scalability across industries.

Turnkey or Partial Module Assembly

Complete integration of mechanical and electronic components—from wire harnesses and PCBs to enclosures and connectors.

Electromechanical Integration

Expert assembly of complex sub-systems including sensors, relays, motors, and control boards into functional modules.

Functional & In-Circuit Testing

Comprehensive testing procedures to ensure every unit meets quality, safety, and performance standards.

Cleanroom & ESD-Safe Workspaces

Controlled environments to handle sensitive components, ideal for medical, aerospace, and precision electronics applications.

Scalable Production Volumes

From rapid prototyping to full-scale production, we adapt to your timeline and volume requirements without sacrificing quality.

Engineering & DFM Support

Our engineering team provides design-for-manufacturability input and process optimization to enhance product reliability and reduce cost.

Industries We Serve

Smartlink Engineering’s module assembly solutions are trusted by global leaders across multiple industries. We understand the strict performance, safety, and compliance standards required in highly regulated sectors—and deliver accordingly.

Automotive

Engine bay wiring, lighting looms, dashboard harnesses

Industrial Equipment

Our modules support industrial automation, robotics, and factory systems—built to withstand harsh environments and operate with precision.

Electronics & Consumer Devices

From IoT units to smart home hubs, we provide compact, reliable module builds for fast-moving electronics markets.

Aerospace & Defense

We assemble mission-critical modules used in avionics, communication systems, and tactical electronics, following strict quality standards.

Medical Devices

We support the medical technology sector with cleanroom-assembled modules for diagnostic tools, monitoring devices, and lab equipment.

Renewable Energy

Our module assembly solutions include battery control units, energy conversion systems, and smart power distribution modules.

Quality Assurance & Certifications

At Smartlink, quality isn’t a checkbox – it’s a culture. Our facilities operate under an ISO 9001:2015-certified Quality Management System. Every module assembly is subjected to:

Thorough inspection of all incoming components

Strict quality controls throughout each assembly phase

Comprehensive final testing including functional and visual checks

If your application requires Class 3 workmanship, UL-listed materials, or RoHS compliance, we can meet those specifications. Documentation and traceability are available upon request.

Frequently Asked Questions

01. What types of modules can Smartlink assemble?

We assemble a wide range of modules including electronic control units (ECUs), sensor modules, power supply units, communication modules, and electromechanical assemblies tailored to your specifications.

02. Can Smartlink handle low-volume prototype assembly as well as high-volume production?

Yes, our flexible production lines are designed to efficiently handle both small prototype runs and large-scale manufacturing without compromising quality.

03. What quality standards does Smartlink adhere to during module assembly?

We operate under an ISO 9001:2015-certified Quality Management System and comply with IPC standards, ensuring thorough inspection and testing at every stage.

04. Does Smartlink provide testing services for assembled modules?

Absolutely. We offer functional testing, in-circuit testing (ICT), and environmental stress testing to guarantee your modules meet performance requirements.

05. Can you assemble modules for regulated industries such as medical and aerospace?

Yes, we have cleanroom facilities and ESD controls in place to meet the stringent requirements of medical, aerospace, and other highly regulated sectors.

06. How does Smartlink handle documentation and traceability?

Every assembly batch is fully traceable with detailed documentation available to support audits, regulatory compliance, and quality assurance.

Get a Quote Today

📩 Contact us today to request a quote or discuss your module assembly project needs. Our team is ready to assist international clients promptly and can support you with drawings, prototypes, or technical specifications.