Custom Cable & Wire Harness Assembly in Malaysia

Smartlink Engineering provides high-quality custom cable harnessing and wire harness assembly services from our ISO 9001:2015-certified facilities in Malaysia. With over two decades of experience, we support global clients across industries including automotive, aerospace, medical devices, and renewable energy. Whether you require prototype development or mass production, we deliver cost-effective, fully tested harness solutions built to international standards.

Why Choose Smartlink for Cable Harnessing?

Smartlink Engineering provides high-quality custom cable harnessing and wire harness assembly services from our ISO 9001:2015-certified facilities in Malaysia. With over two decades of experience, we support global clients across industries including automotive, aerospace, medical devices, and renewable energy. Whether you require prototype development or mass production, we deliver cost-effective, fully tested harness solutions built to international standards.

- ISO 9001:2015-certified manufacturing

- Custom harness solutions tailored to your design or specifications

- Competitive pricing and flexible batch volumes

- Global shipping and export-friendly operations (LMW licensed)

- Decades of experience across multiple industries

- End-to-end service: from design assistance to final testing

Our Cable

Harnessing Capabilities

Smartlink offers a full spectrum of wire and cable harness assembly services, backed by advanced tools and trained personnel.

Wide Range of Assemblies

We manufacture harnesses ranging from simple jumper wires to complex multi-branch looms for high-power and signal applications. We accommodate various cable types, gauges, shielding requirements, and jacket materials.

Connector & Terminal Expertise

Our technicians are skilled with all major connector systems, including Molex, JST, TE, Deutsch, and custom pin headers. Whether it’s crimped, soldered, or overmolded terminations, we meet precise mechanical and electrical specs.

Testing & Quality Control

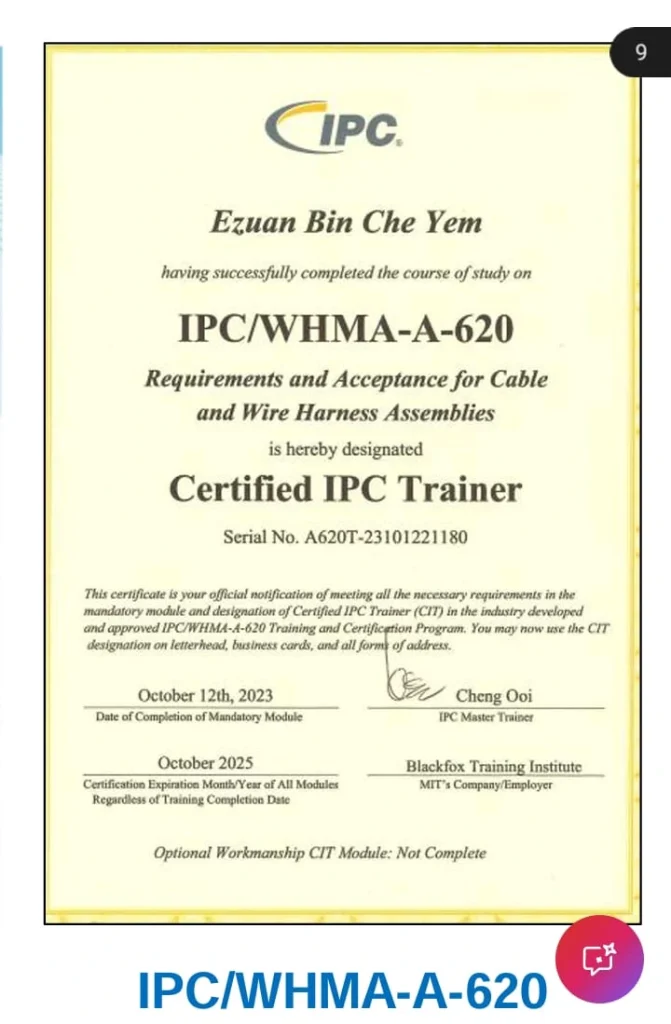

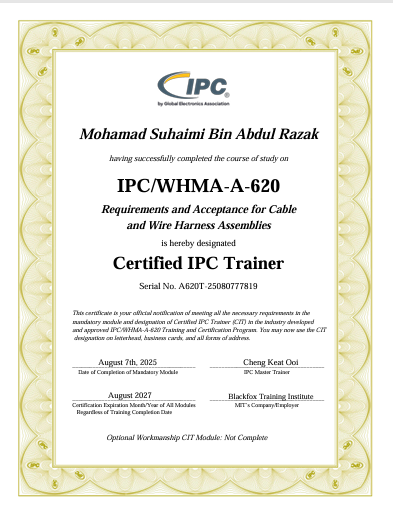

Every assembly is 100% electrically tested for continuity and insulation resistance. We follow IPC/WHMA-A-620 workmanship standards and provide inspection documentation upon request.

Build-to-Print & Custom Design Support

Have a drawing or a prototype? We manufacture based on your documentation or collaborate on custom harness designs with full prototyping and engineering input.

Integrated Solutions

Looking for more than cables? Our team seamlessly integrates harnesses into control panels, modules, and box builds, giving you a one-stop solution that simplifies vendor management and boosts efficiency.

Handling HMLV RFQs

Potential customers should know that we are also able to handle HMLV

Industries We Serve

Our team has extensive experience supporting a wide range of industries with application-specific harness solutions:

Automotive

Engine bay wiring, lighting looms, dashboard harnesses

Industrial Equipment

Machine wiring, PLC/control cables, power distribution

Electronics & Semiconductor

Fine-gauge interconnects, ribbon cables, EMI-shielded assemblies

Aerospace & Defense

High-reliability wiring for avionics, unmanned systems, and tactical platforms

Medical Devices

Patient monitoring cables, imaging equipment harnesses, clean-assembled wiring

Renewable Energy

Solar panel connectors, wind turbine cable looms, battery management system wiring

Our familiarity with sector-specific standards (e.g., IATF 16949, IPC, RoHS) ensures that your harnesses meet both performance and regulatory demands.

Quality Assurance & Certifications

At Smartlink, quality isn’t a checkbox – it’s a culture. Our facilities operate under an ISO 9001:2015-certified Quality Management System. Every harness undergoes:

Incoming component inspection

Process control at each assembly stage

100% final electrical and visual inspection

If your application requires Class 3 workmanship, UL-listed materials, or RoHS compliance, we can meet those specifications. Documentation and traceability are available upon request.

Frequently Asked Questions

01. What is cable harnessing? Is it the same as wire harness assembly?

Yes, these terms are used interchangeably. Cable or wire harnessing refers to bundling wires and connectors into a compact assembly to transmit electrical signals or power within equipment.

02. Why source cable harnesses from Malaysia?

Malaysia offers high-quality manufacturing at competitive costs, supported by skilled labor and government incentives. With Smartlink’s ISO-certified processes and LMW status, international buyers enjoy reliable quality and smooth import/export handling.

03. Can Smartlink handle custom harness designs?

Absolutely. We offer build-to-print manufacturing and design support for custom harnesses. Whether you need prototyping or complex multi-circuit assemblies, our engineering team is here to help.

04. Does Smartlink support low-volume orders?

Yes. We work with clients at every stage, from small-batch prototypes to large-scale production. Our flexible operations are ideal for high-mix, low-to-medium volume needs.

05. What certifications do your cable harnesses comply with?

Smartlink is ISO 9001:2015 certified. We follow IPC/WHMA-A-620 standards for assembly quality and can provide RoHS, UL, or other compliance documentation depending on your project needs.

Get a Quote Today

📩 Contact us today to request a quote or discuss your project requirements. Our team responds promptly to international inquiries and can help you get started with drawings, samples, or specifications.