An experienced and dedicated team that is focused on customers’ need. Smartlink’s organisation has formed an efficient, effective and flexible project and supply chain management team, supported by reliable external and internal forces to cope for the dynamic and complexity demand from customers. Customers are closely involved in this process, driven by cost, time and quality with clear and transparent both ways communications.

SUPPLIER NETWORK

With many years of experiences working together with local and international supply chain , Smartlink Engineering have established a strong supplier’s network that helps in providing a competitive and excellent quality goods for our customers. In addition, Smartlink is committed in providing consultation for sourcing alternative material suppliers to fulfill customer’s specification.

SUPPLIER NETWORK

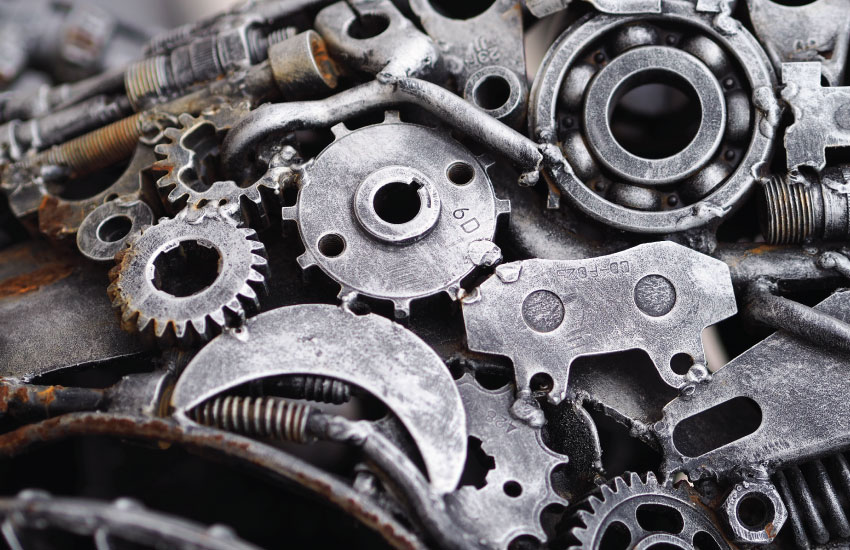

Machine Assemblies

We build and assemble machines with precision, ensuring reliability and efficiency.

Sub-module Assembly

We integrate components into functional modules, streamlining production and performance.

We provide high-quality wiring solutions for organized, durable, and efficient systems.

Electrical Parts

PCBA, Sensors, Connectors,Wires, Drivers,

and Motors.

Heat Treatment Process

Carburizing/ Carbon Nitriding, Brazing, CVD Coating (Tin/TiCN/TiBN/Multilayer), QPQ, Stress Relieving / Normalizing / Annealing, Hardening & Tempering.

Manpower Supply

We provide highly trained operators, technicians and engineers to support customer’s production.

Surface Treatment Process

Carbonizing, Hard Anadizing, Anadizing, EN Plating, Zinc Plating, Gold Plating, Chroming, Passivation, Powder Coating, and Paint Spraying.

List of Production Machines

Metal Fabrication Wtc

| MAJOR M/C TYPE | CAPACITY/ACCURACY | NUMBER OF UNITS |

|---|---|---|

| DURMA FIBER LASER MACHINE | 5′×10′ 2KW | 1 |

| DURMA FIBER LASER MACHINE | 5′×10′ 6KW | 1 |

| YAWEI BENDING MACHINE | 12FT, 220 TON | 1 |

| YAWEI BENDING MACHINE | 10FT, 110 TON | 1 |

| YAWEI BENDING MACHINE | 4FT, 35 TON | 1 |

| ABB WELDING ROBOT | 350 Amp | 1 |

| CNC FANUC ROBODRILL | 600×400MM | 1 |

| TIME SAVER POLISHING MACHINE | 800×1000 | 1 |

| LANUS POLISHING MACHINE | 600 X (LENGTH) | 1 |

| MANUAL LATHE MACHINE | 2 | |

| MANUAL VERTICAL MILLING MACHINE | 5 HP | 2 |

| MIG WELDING MACHINE | 350 Amp | 2 |

| MIG + MAG FRONIUS WELDING MACHINE | 220 Amp | 2 |

| HANDHELD FIBER LASER WELDING MACHINE | 1500W | 1 |

| SPOT WELDING DC INVERTER | PWM500 | 1 |

| TIG WELDING MACHINE | 200 AMP | 7 |

| YAWEI TUBA LASER MACHINE | Ø16-200, 6200M, 3KW | 1 |